Zirconia/titania sol have been developed using Nissan Chemical’s proprietary manufacturing technology. These are highly concentrated and stable metal oxide sols that can be used in a binder for optical applications, titanium precision casting and various catalysts.

NanoUse is available in three types: NanoUse® ZR, NanoUse® OZ, and NanoUse® OT.

NanoUse® ZR

NanoUse® ZR is a water-dispersed zirconia sol with high concentration and chlorine-free properties. This is used as a binder for titanium precision casting and various catalysts.

| Grade | ZR-40BL |

|---|---|

| Solid content (%) | 40 |

| Particle size *1 | 90 |

| pH | 9.6 |

The figures above are general properties, not guaranteed properties.

Through patented production technologies Nissan Chemical has developed an unprecedented water-based zirconia sol. NanoUse® ZR offers excellent stability at a high concentration with the following points of interest:

- The primary particle size of zirconia in sol is around 7 nm and exists as micro-colloidal zirconia in a globular aggregate form which has a large surface area with excellent binding properties.

- It reaches its equipotential point at pH 5.5~6.5 and is stable in acid and alkali systems.

- Because alkali zirconia sol has properties similar to silica sol, it can be mixed with silica sol. Acidic zirconia sol can be mixed with alumina sol.

- Acidic zirconia sol exhibits good compatibility with alcohols.

- It does not contain chloride ions (Cl), as conventional zirconia sols do.

- High baking strength as well as good burning strength can be achieved.

Additionally, we provide a hybrid sol with an enriched binder function and a micro-particle sol that is doped by yttria so that you can choose the one that suits your specific application.

Properties and applications of NanoUse® ZR

- Adherability and coating

- Hydrophilicity; Antistatic property

- Impregnating and filling capability

- Cationic and anionic property

- Fire-deterrent property

- Binding and adherence

- Reactivity

- Heat resistance, fire resistance

- Ion exchangeability (inorganic ion-exchange member)

- Anti-corrosiveness

- Abradability

- High specific surface area

- Chemical resistance

- High refractive index

- Deodorizing capability

Electric charge

Heat resistance

of dried gel of ZR-40BL. ZR-40BL can be used as a binder under high temperature environment (e.g. 1000℃).

Particularly effective in the following applications:

- Binder for titanium precision casting

- Electrodes and solid electrolyte for fuel cells

- Carrier and binder for the synthetic catalysts and fuel cells

- Carrier and binder for automotive catalysts

- Filler having a high refractive index for coating materials

- Micro-filler for nanometer composite

- Binder for molding fire deterrent members and ceramics

- Raw materials for fine ceramics

- Polishing slurry

- Surface-treatment agent for ceramics and metals

NanoUse® OZ/OT line-up and physical properties

Zirconia/titania sols dispersed in water/organic solvents have been developed for optical applications.

These have high dispersibility and a high refractive index and can be used as a refractive index modifiers and reflective materials.

NanoUse® OZ

NanoUse® OZ is a zirconia sol dispersed in water/organic solvents with high light-resistance.

| Grade | OZ-S2OH (Experimental sample) | OZ-S3OM | OZ-S4OK-AC (Experimental sample) | OZ-S3OP-AC (Experimental sample) |

|---|---|---|---|---|

| Main component | ZrO2 | |||

| Particle refractive index | 1.85 ~ 1.90 | |||

| Dispersion solvent | Water | Methanol | MEK | PGME |

| Concentration | 20 | 30 | 40 | 30 |

| pH | Weak acidity | |||

| Viscosity | 1.0 – 10.0 | |||

| Particle size | 10 ~ 15 (primary particle size) | |||

NanoUse® OT

NanoUse® OT is a titania sol dispersed in water/organic sovents with a higher refractive index than zirconia sols. The lineup includes a high refeactive index grade and a highly light-resistant grade with inhibition to photocatalytic activity.

| Grade | High light resistance | High refractive index | ||||

|---|---|---|---|---|---|---|

| OT-RA305W7-20 | OT-RA305M7-20 | OT-RA305K7-AC (Experimental sample) | OT-RA205P7-AC (Experimental sample) | OT-RB300M7-20 (Experimental sample) | OT-RB200K7-AC (Experimental sample) | |

| Main component | TiO2 | |||||

| Particle refractive index | 2.1 ~ 2.2 | 2.2 ~ 2.3 | ||||

| Dispersion solvent | Water | Methanol | MEK | PGME | Methanol | MEK |

| Concentration | 30 | 30 | 30 | 20 | 30 | 20 |

| pH | Weak acidity | Weak acidity | ||||

| Viscosity | 1.0 – 10.0 | 1.0 – 10.0 | ||||

| Particle size | 5 ~ 10 (primary particle size) | |||||

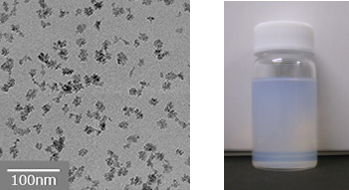

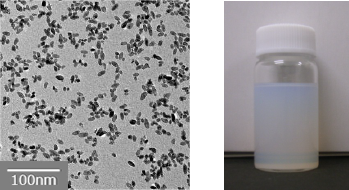

TEM images and external views

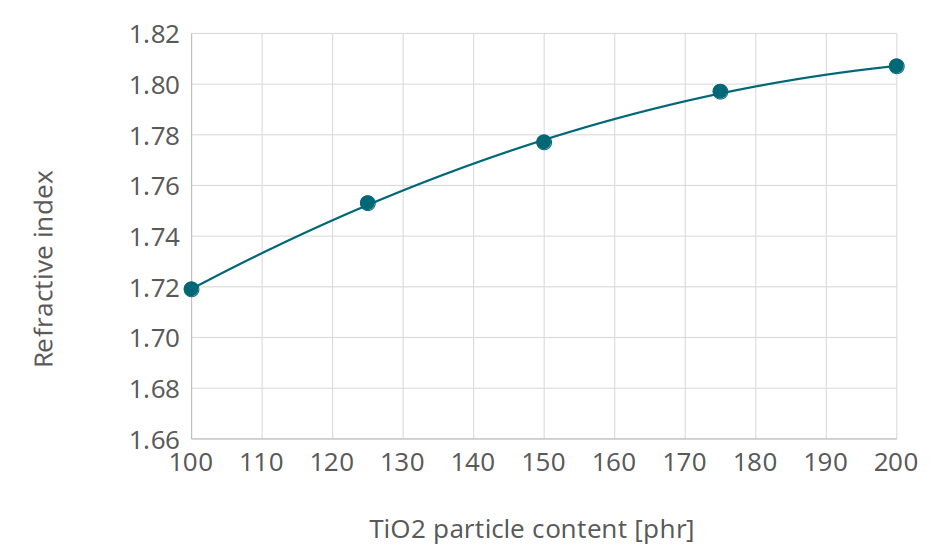

Particle addition amount and film refractive index

- Filler:OT-RB300M7-20

- Binder:DPHA(hexafunctional acrylic resin)

- Substrate:glass

- Film thickness:1μm

The refractive index can be adjusted to any desired refractive index by changing the amount of particles added.

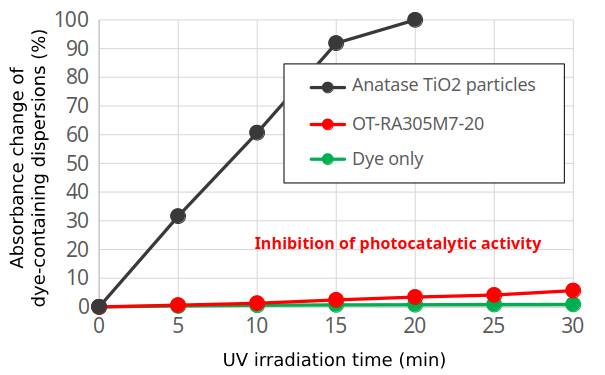

Light resistance

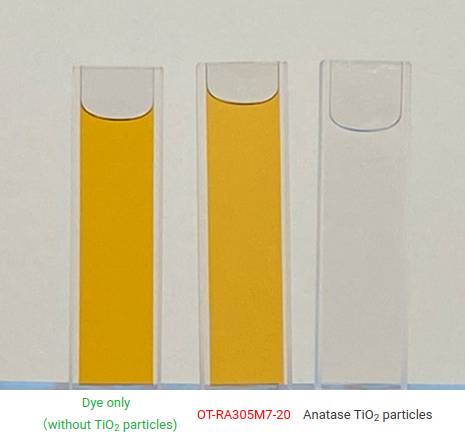

During TiO2particle UV irradiation, the dye decomposes due to the photoactivity of TiO2. OT-RA305M7-20, in which photoactivity is suppressed, significantly reduces the decomposition of the dye.

After adding an organic dye (sunset yellow) to a light-resistant TiO2particle dispersion, the dye-containing dispersion was irradiated with UV light and the absorbance of the dye-containing dispersion was measured.

Coating film properties

- Filler:OT-RA305M7-20

- Binder:DPHA(hexafunctional acrylic resin)

- TiO2 content:100phr

- Substrate:sapphire glass

- Film thickness:1μm

| Refractive index | 1.68 |

|---|---|

| Haze | 0% |

Low Haze, high transparency coatings can be formed.